Twisting cotton fibers into strands

Our spinning unit, turns quality cotton into high grade yarn with state-of-the-art modern machineries. The superior quality raw cotton selected by our quality experts are mixed appropriately and processed with Cotton Contamination Cleaner machines to discard impurities. We maintain uniform, incomparable quality from mixing of cotton to error-free yarn with a production capacity of 30,000 kg/day.

Knitting

Turning Yarn into Cloth

With latest imported knitting machines and paramount precision, we produce uniform, high quality and comfort fabrics in diverse texture and GSM. We knit different types of fabrics such as Interlock, Rib, Jersey, Airtex, Honey Comb, Lycra Jersey, Fleece and Mini Jacquards in Various structures and patterns. Our Production capacity counts to 6 tons/day.

Dyeing

Processing integrated with best in class

our dyeing unit is integrated with the best-in-class Air-Flow Technology machineries giving exceptional fastness and shade-matching. We employ azo-free, environmental friendly dyes and chemicals and treat all the effluents rightly before discharge. Our modern computerized laboratory supports the qualified chemists to take care of the color accuracy. Our division is inbuilt with a production capacity of 20 tons/day.

Fabric Checking

The Knitted Fabric That Spells Quality

Superior quality yarn is outsourced and knitted by the latest knitting machines, processed at the best dyeing units and after all the quality parameters are checked, the fabric is passed on to production.

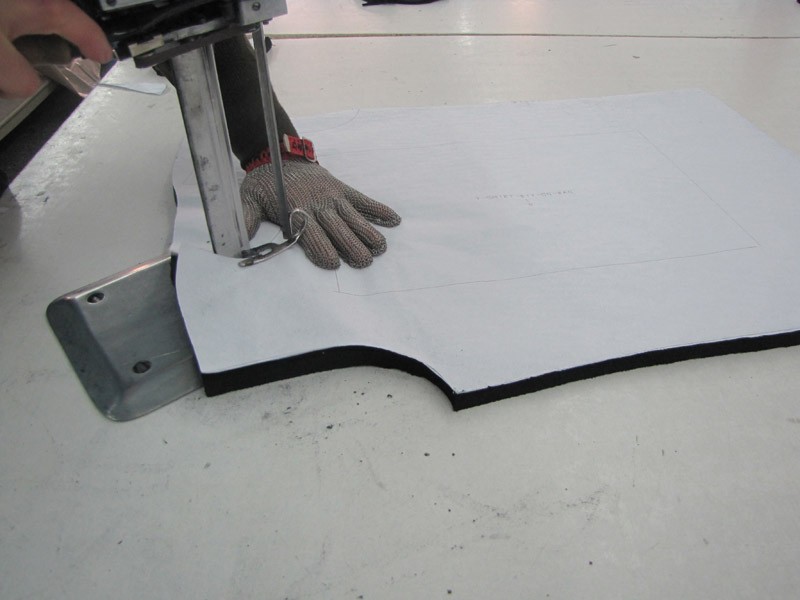

Cutting

Agile Precision

Manual expertise and GERBER automatic lay cutting machines speed up the production by cutting the fabric into desired sizes for different specifications. The cut panels are checked, numbered and passed on to the Feeding Section to arrange the fabric for stitching.

Printing & Embroidery

Value Additions

Lasting impressions are made manually and by automatic MHM printing machines and intricate embroidery by BARUDAN and SWF machines with sequin and cording attachments give that special touch to the beauty of the garments .We have a printing capacity of 5,000 pcs per day with a glass table and new state-of-the-art technology. Our print technician’s skills make us stand proud in the market. Quality at source and controls at every stage makes printing another feather in our cap to stand apart from competitors. This unit practices and is approved for production.

Sewing

Agile Precision

The Stitching Unit has 50 high end sewing machines by JUKI Lockstitch, PEGASUS Flat lock and Over lock, all measuring up to the intricate complexity of stitching. The hard working skilled team takes extra care and guarantees the best fit of each garment that satisfies all the parameters and also ensures quick delivery.

Washing

The Gentle Wash

The Washing Unit comprising of RAMSONS machines and the zero effluent discharge plant ensures pre-wash for selected fabrics and post-wash for garments with different finishing

Finishing

Error-free to the end

Manual checking, needle detection and stain removal is a regular part of the post-stitching inspection to ensure a contamination-free garment.